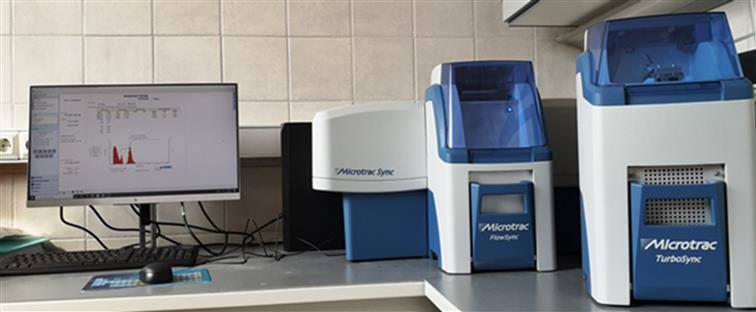

The SYNC particle size and shape analyzer utilizes three lasers emitting red and blue light, enabling the detection of submicron particles and multimodal distributions. Scattered light on particles is analyzed using an algorithm based on Mie's principle, providing precise size distributions for spherical or angular particles. It operates with liquid dispersion via the FlowSYNC unit (with options for water and alcohol) or air dispersion via the TurboSYNC unit. An ultrasonic probe disperses agglomerated materials for consistent sample dispersion. Additionally, it conducts dynamic image analysis, crucial for studying particle morphology.

Contact: dr. Mateja Štefančič (

mateja.stefancic@zag.si)

Rental of equipment and access to it together with a qualified operator is possible by prior arrangement. The price of the investigation depends on the complexity of the experiment. The equipment was purchased under the ARRS public tender for co-funding of scientific research equipment package 18.