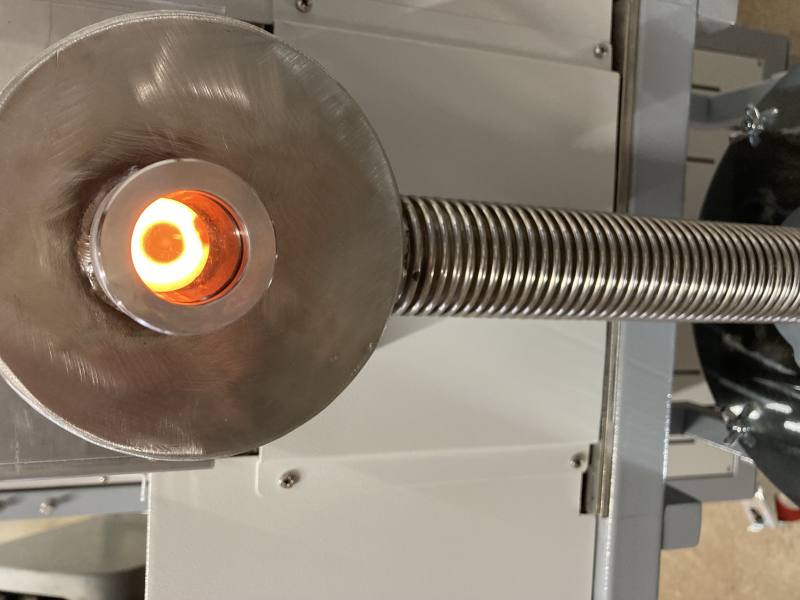

Rotary tube furnace enables the production of various materials, such as cement clinker, preparation of light aggregates, thermal activation of materials for mineral additives (e.g. clay calcination), etc. The furnace has the shape of a tube that rotates during operation. The tube is placed at a slight angle so that the material passes smoothly between the areas to the final / target temperature. Furnace has 3 independent heating zones of total length (3x330mm) 1000mm. Each zone can be controlled independently. Maximum operation temperature of furnace is 1500 ° C but since we are currently using Mullite based tube the maximum allowed operating temperature is 1300 ° C. The passage of material between the zones allows rotation (4-20 rpm) and tilt of the tube (up to 15 °). The built-in vibration system ensures easier passage of material between zones. The tube is made of refractory material (mullite tube), which withstands temperature shocks, its diameter is Ø 120 mm and its length approx. 2000 mm. The tube material can be adapted to our needs, they can be made of quartz, ceramic (mullite, SiC) or metal (recrystallized alumina, aluminium, zinc, etc.). The furnace is designed for continuous material processing. It is equipped with an initial dispenser that allows continuous filling and a final output system of the processed material. The furnace is equipped with a simple computer system (Omron E5CC Technical specs), which is on the outer frame of the furnace and allows easy operation of the furnace. Computer system controls the sintering temperature, the heat treatment time of the material, the inclination angle of the tube, the rotation speed of the tube, etc. Dual shell, floor-standing casing allows temperature stability (low external temperatures and high inner temperature). Galvanize coated and powder painted outer casing. Kanthal Globar SiC quality heating elements placed at sides, total of 18 elements. Alarm for preventing over heating of the furnace is installed, protecting the insulation material and the heating elements. The approx. power rating is 15.000 W (connecting voltage; three phase 380/220 V 3-N/PE, 50/60Hz). UPS power supply with the rotation system is recommended against blackouts and for the continuation of rotation until the system is cooled to a stable temperature of environment.

Rental and access to equipment together with a qualified operator is possible by prior arrangement.

Equipment was purchased within Slovenian Research Agency public call for co-financing research equipment Paket 19.

Contact: Sabina Dolenec, Ph. D. (Geology) (sabina.dolenec@zag.si)