Meeting of partners in the ACES project for nuclear power plant safety

17.05.2023

At the Slovenian National Building and Civil Engineering Institute, we are actively involved in the European project ACES, which will improve the assessment of the safety performance of critical concrete infrastructure by eliminating scientific and technological gaps for the safe and long-term operation of nuclear power plants. Last week, a 3-day meeting was held at the institute’s headquarters in Ljubljana, which was attended by our partners from abroad.

ACES project for nuclear power plant safety

The project of the EU Horizon 2020 program brings together experts from 10 different institutions from the European Union, Ukraine and the United States of America, who are researching the aging and deterioration of concrete in nuclear facilities. The purpose of our research is to determine safety margins that have been introduced using conservative approaches during design and are defined by standards and codes that apply throughout the life of these facilities.

The project is coordinated by Dr Miguel Ferreira from the Finnish Institute VTT. Activity coordinator and project manager at ZAG is assoc. prof. dr. Andraž Legat. Actively involved are also M.Sc. Nina Gartner and Dr Miha Hren.

About the event

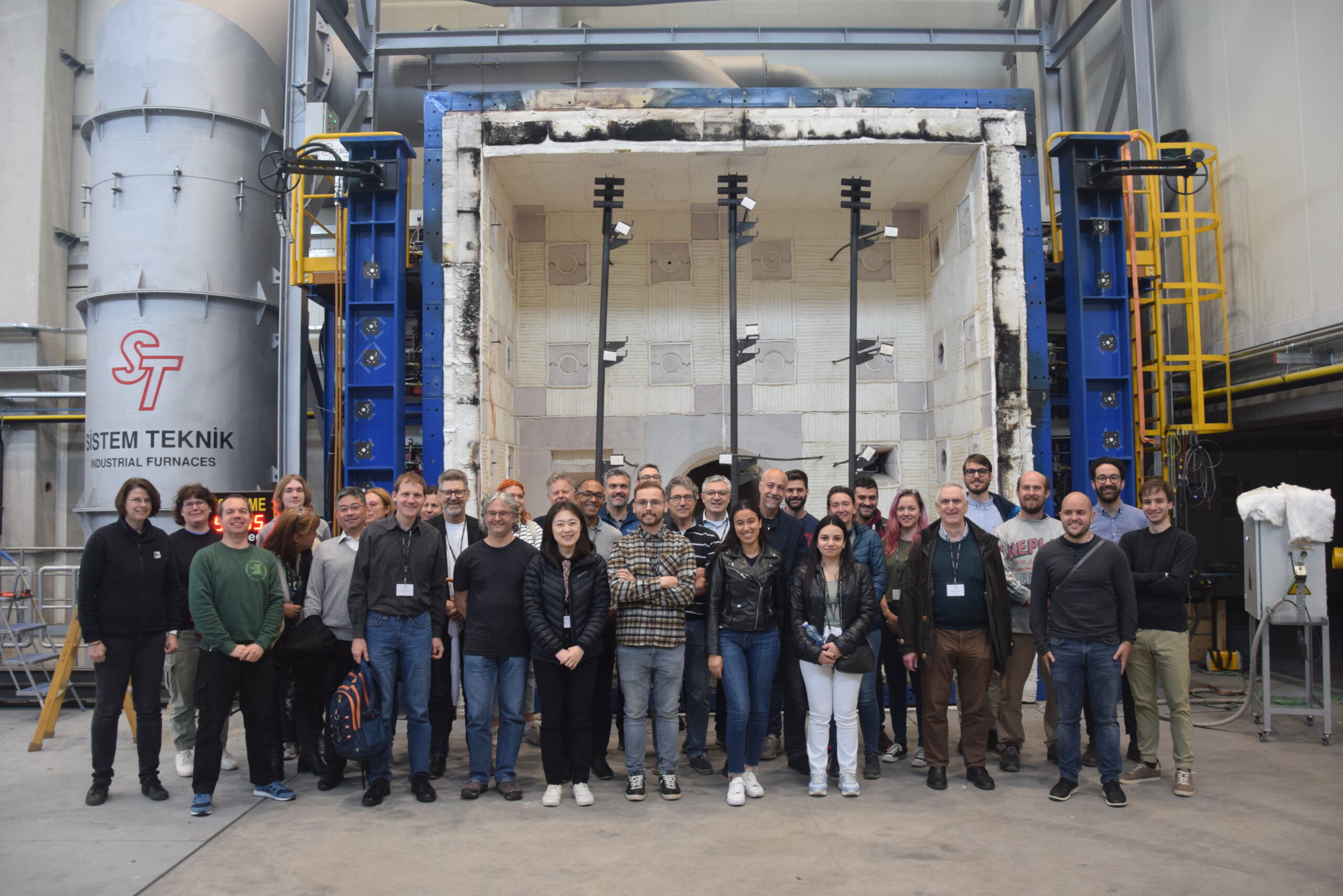

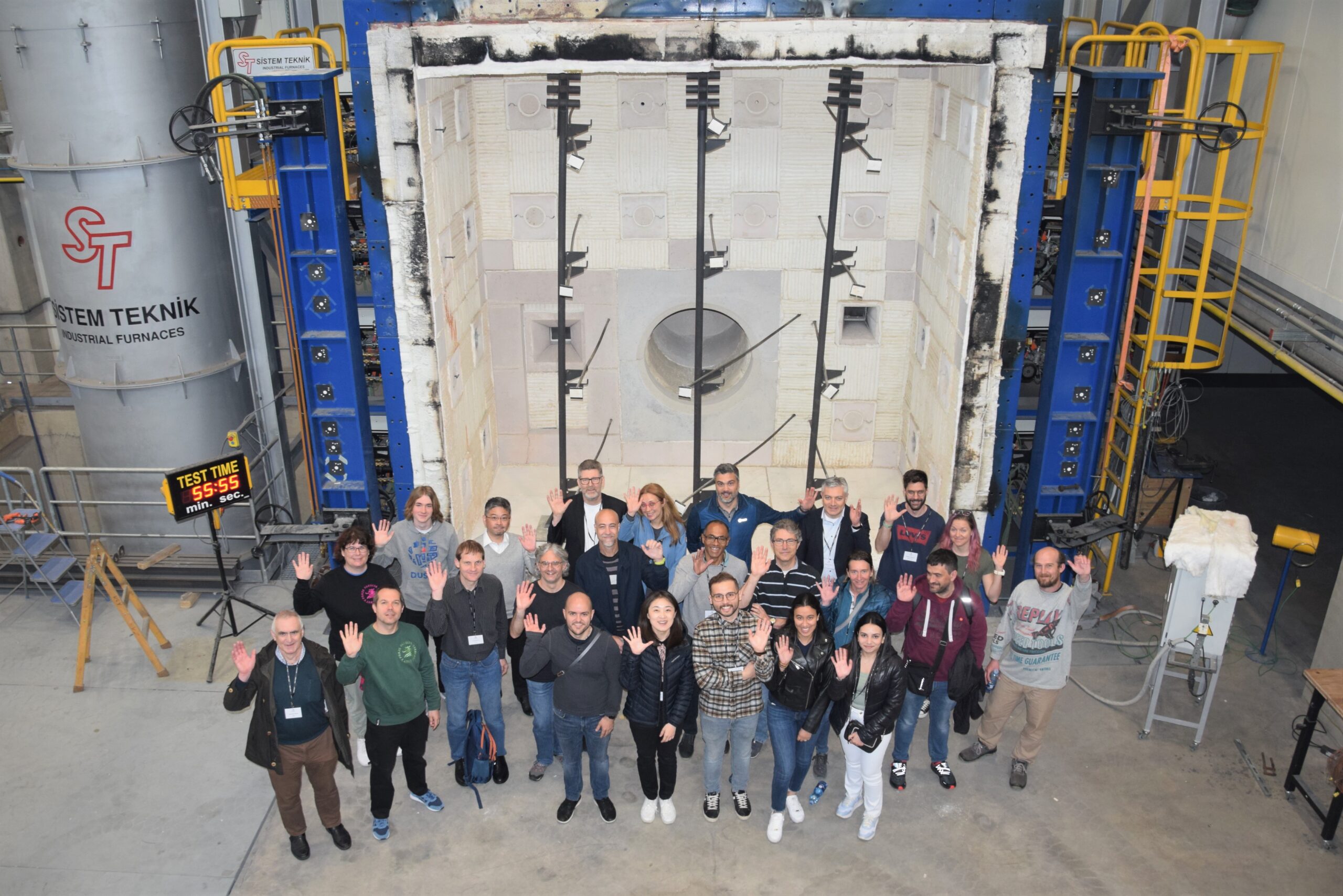

At the third meeting of the project partners, which took place between May 10 and 12 at the ZAG headquarters in Ljubljana, the results to date and future activities were presented. 30 participants were present, and another 26 attended online.

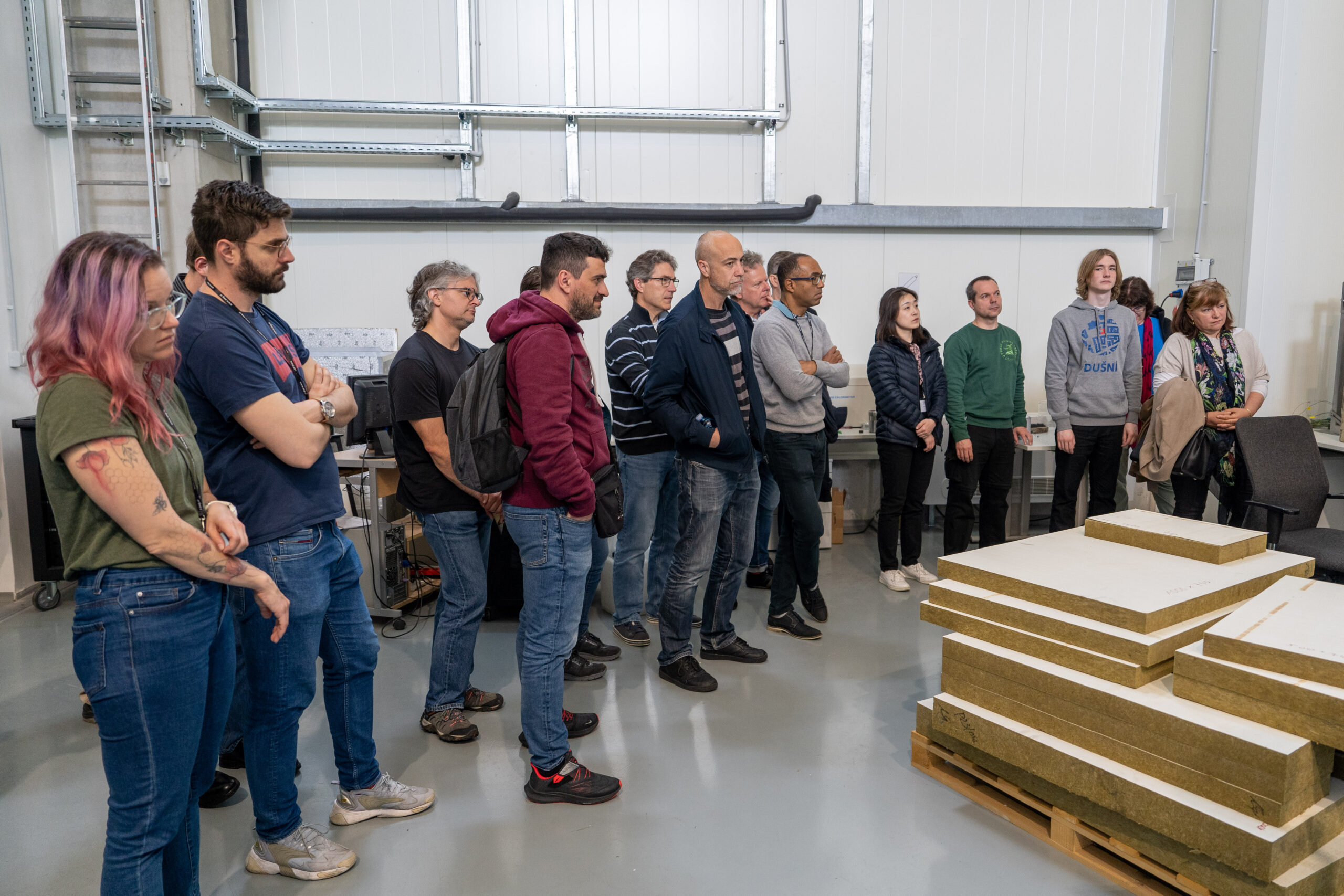

The joint part of the meetings dealt with the general contents of project management and dissemination, while the researchers of the individual working projects presented the selected contents of the research areas of the project. The invited lecture entitled “Post irradiation examination (PIE) on irradiated aggregate” was delivered by prof. Ippei Maruyama from the University of Tokyo, a member of the Advisory Board of the project. The event was also attended by a representative from the Administration of the Republic of Slovenia for Nuclear Safety, which belongs to the group of end users.

The participants also had the opportunity to see some of ZAG’s laboratories: the Laboratory for Metals, Corrosion and Anti-Corrosion Protection, the Construction Hall and the recently opened Fire Laboratory.

ZAG’s role in the project

In addition to group meetings and meetings of the Advisory Board and the General Assembly, the program also included meetings of individual working packages. The Laboratory for Metals, Corrosion and Anti-Corrosion Protection at ZAG is included in the ACES project as a leading partner of Work Package 2, of which the content is the study of corrosion of steel liners in concrete (Corrosion assessment of embedded liners in concrete).

Work Package 2 focuses on two of the most safety-critical parts of reinforced concrete structures of nuclear power plants: chloride-induced corrosion of steel-concrete pipes and crevice corrosion of steel linings embedded in the concrete of the containment facility. A thorough and timely assessment of the corrosion state is difficult due to the lack of information and poor accessibility to the damage site, so the aim of work group 2 is to, through experimental work

- provide basic information for modeling,

- provide non-destructive inspection and

- facilitate appropriate preventive measures.

Together with the French Center for Nuclear Research (CEA) and the Belgian leading expert and research center for power technology (ENGIE LAB), we are involved in the evaluation of suitable non-destructive techniques (NDT) for the corrosion inspection of steel cylinder concrete pipes (SCCP) ). At CEA and ENGIE LAB, they have two different pipes, which have already been used in a nuclear power plant and have various corrosion damages. Last year, ENGIE LAB carried out manual measurements inside the pipe using two selected measurement techniques (Pulsed Eddy Current, Half-cell potential mapping) to detect corrosion processes on the steel lining embedded between two concrete layers. In the next phase of research, both techniques will be implemented on a robotic platform with a manipulator for their management, which is being developed by CEA as part of the project. This will allow an easier inspection of the inside of the pipe and thus earlier detection of corrosion damage.