Projekt J2-3035

Naslov in šifra projekta / GA no.

J2-3035 Sinteza alkalijsko aktiviranih materialov s pomočjo mikrovalov

J2-3035 Synthesis of alkali activated materials with microwave heating

Partnerji projekta in njihovi logotipi

Vodja projekta: Barbara Horvat

Vodja projekta na ZAG: Barbara Horvat

Trajanje projekta: 01. 10. 2021 – 30. 09. 2024

Višina financiranja: ARRS: 3 leta, 2344 ur letno, cenovna kategorija C

Povzetek projekta SI:

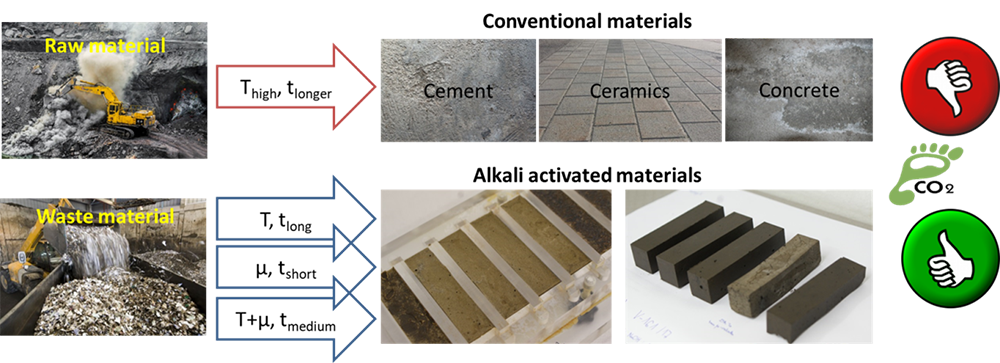

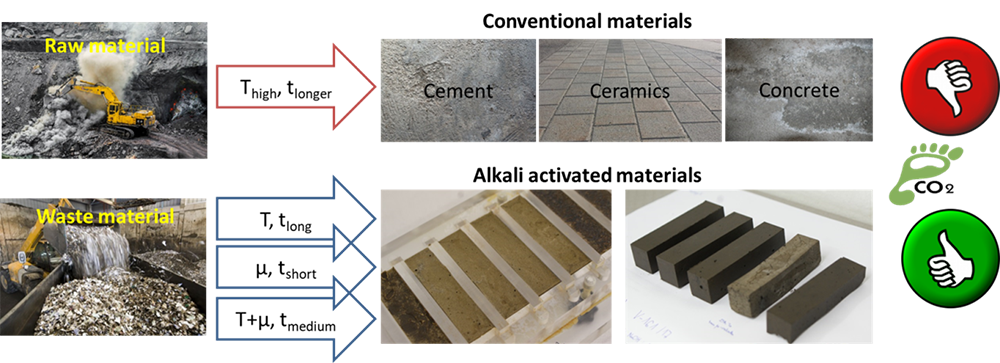

Alkalijsko aktivirani materiali (AAM) so perspektivna alternativa konvencionalnim gradbenim materialom (cement, beton, keramika), saj je energija potrebna za izdelavo manjša, tj. čas in temperatura priprave sta nižja, posledično tudi ogljični odtis.

Slika 1. Primerjava konvencionalnih in alternativnih proizvodov gradbenih materialov.

Materiali, ki se lahko uporabljajo kot prekurzorji, morajo vsebovati dovolj Si in Al v amorfni fazi ter čim manj elementov iz 1. skupine, ki se jih doda naknadno z aktivatorjem, saj je končno idealno množinsko razmerje elementov 1. skupine:Al:Si vseh sestavin skupaj enako 1:1:1.9. Izbrano razmerje Al:Si se lahko doseže z mešanjem ustreznih prekurzorjev.

Najbolj uporabljan prekurzor je metakaolin, ki velja kot standard v alkalni aktivaciji. Kot aktivator v reakciji pa se večinoma uporabljajo NaOH, KOH, Na-vodno steklo ter K-vodno steklo.

V prvi fazi reakcije poteka najprej raztapljanje v alkalnem mediju, nato transport elementov, tvorba alumosilikatnih-monomer (povezovanje Al in Si s O v tetraedre), polikondenzacija (in dehidracija) v alumosilikatno mrežo, ki je večinoma amorfna. Prvi fazi reakcije sledi nega na nizkih temperaturah (pod 100 °C), tj. nadaljnja dehidracija do končnega produkta, tj. AAM. V praksi so AAM bili že implicirani v Avstraliji, najprej za pisto na letališču v kraju Brisbane, nato pa še za javno zgradbo v kraju Queensland.

Cilj tega projekta je testirati vpliv elektromagnetnega valovanja v območju mikrovalov na različne faze sinteze AAM, tako začetne, ko z mikrovalovi volumetrično povečamo temperaturo alkalno aktivirane zmesi in tako pohitrimo reakcijo, skrajšamo čas sinteze in prihranimo porabljeno energijo, kot tudi v kasnejših fazah, ko vplivamo na dehidracijo (sušenje) in zlivanje.

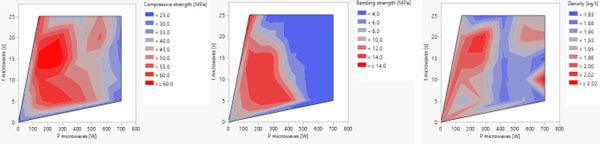

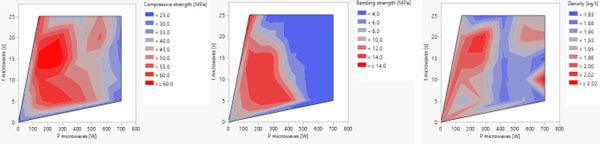

Slika 2. (a) Tlačna trdnost, (b) upogibna trdnost in (c) gostota 28 dni starega alkalijsko aktiviranega elektrofiltrskega pepela, ki kaže unikatno dozimetrično odvisnost od trajanja in moči obsevanja z mikrovalovi.

Za doseganje teh ciljev se bo projekt osredotočil na:

- kemijsko in mineraloško analizo metakaolina,

- določitev optimalne mešanice prekurzorja ter alkalnih aktivatorjev,

- izbiro mikrovalovne pečice za sintezo AAM ter izbiro ustreznih kalupov za uporabo v mikrovalovni pečici,

- optimizacijo spremenljivih parametrov mikrovalov v vseh fazah sinteze AAM za doseganje optimalnih mehanskih lastnosti AAM,

- implementacijo pridobljenega znanja pri uporabi odpadnega materiala za prekurzor.

Projekt je razdeljen v 5 delovnih sklopov vezanih na specifične cilje projekta, ki ga bodo izvajali ZAG – Oddelek za materiale, KI – Odsek za anorgansko kemijo in tehnologijo. Obe skupini imata že veliko izkušenj pri pripravi in karakterizaciji AAM iz različnih prekurzorjev oz. analizi materialov z NMR.

Pridobljeno znanje bo podlaga za razvoj različnih izdelkov z boljšimi mehanskimi lastnostmi pripravljeni v krajšem času z manj vložene energije. V projektu bomo tako dobili novo interdisciplinarno znanje, ki bo povezovalo tehnologijo in okoljske vidike.

Povzetek projekta EN:

Alkali activated materials (AAM) are a promising alternative to conventional building materials (cement, concrete, ceramics) because the energy required to produce AAM is lower, i.e. preparation time and temperature are lower, and consequently also carbon footprint.

Figure 1. Comparison of conventional and alternative production of building materials.

Materials that can be used as precursors must contain sufficient amount of Si and Al in the amorphous phase and as few elements of group 1 as possible, which are added later with the alkali activator since the final ideal ratio of elements of group 1:Al:Si of all of the ingredients together is 1:1:1.9. The selected Al:Si ratio can be achieved by mixing the appropriate precursors.

The most used precursor is metakaolin, which is considered as the standard in alkali activation. While for alkali activator mostly used are NaOH, KOH, Na-water glass and K-water glass.

First phase of the reaction in the alkaline medium, dissolution of the precursor, is followed by the transport of the elements, alumosilicate monomers formation (binding of Al and Si with O into tetrahedra), polycondensation (and dehydration) into the alumosilicate network, which is mostly amorphous. The first reaction phase is followed by the curing at low temperatures (below 100 ° C), i.e. further dehydration to the final product, i.e. AAM. AAM has already been implemented in real-life building industry in Australia, first for an airport runway in Brisbane, and then for a public building in Queensland.

The aim of this project is to test the influence of electromagnetic waves in the microwave spectrum on different phases of AAM synthesis, both initial, i.e. when microwaves volumetrically increase the temperature of the alkali activated mixture, thus speeding up the reaction, shortening the synthesis time and lowering the used energy, as well as in the later stages when microwaves affect dehydration (drying) and sintering.

Figure 2. (a) Compressive strength, (b) bending strength and (c) density of 28 days old alkali activated fly-ash showing unique dosimetric dependence on duration and power of irradiation with microwaves.

To achieve these goals, the project will focus on:

- Chemical and mineralogical analysis of metakaolin,

- Determination of the optimal mixture of precursor and alkali activators,

- Selection of a microwave oven for synthesis of AAM and selection of suitable moulds that can be used in a microwave oven,

- Optimization of variable parameters of microwaves at all stages of AAM synthesis to achieve optimal mechanical properties of AAM,

- Implementation of the acquired knowledge with using waste material for the precursor.

The project is divided into 5 work packages related to the specific project objectives which will be performed by ZAG – Department of Materials, KI – Department of Inorganic Chemistry and Technology. Both groups already have extensive experience in either preparation and charcterization of AAM from different precursors or analysis of materials with NMR.

The acquired knowledge will be the basis for the development of various products with better mechanical properties, prepared in a shorter time with less invested energy. The project will thus provide new interdisciplinary knowledge that will combine technology and environmental aspects.

Faze projekta in opis realizacije (delovni sklopi) SI

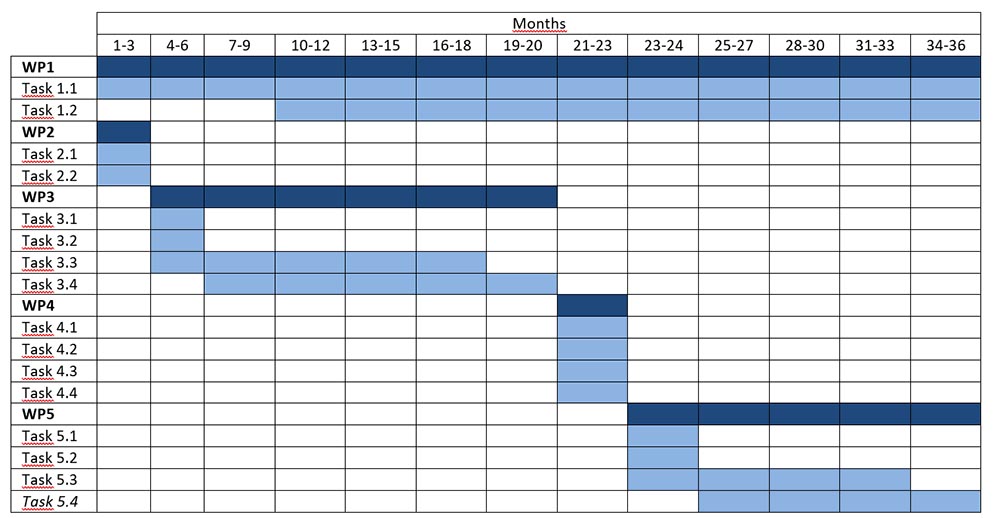

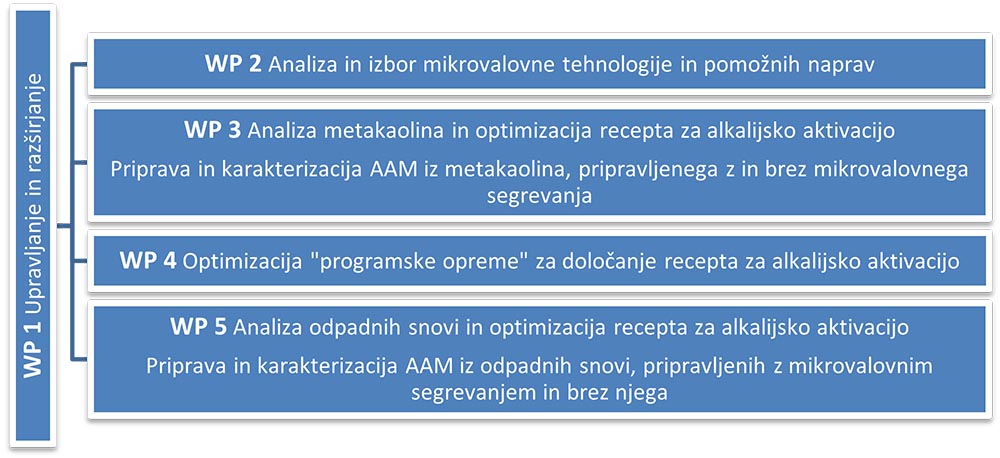

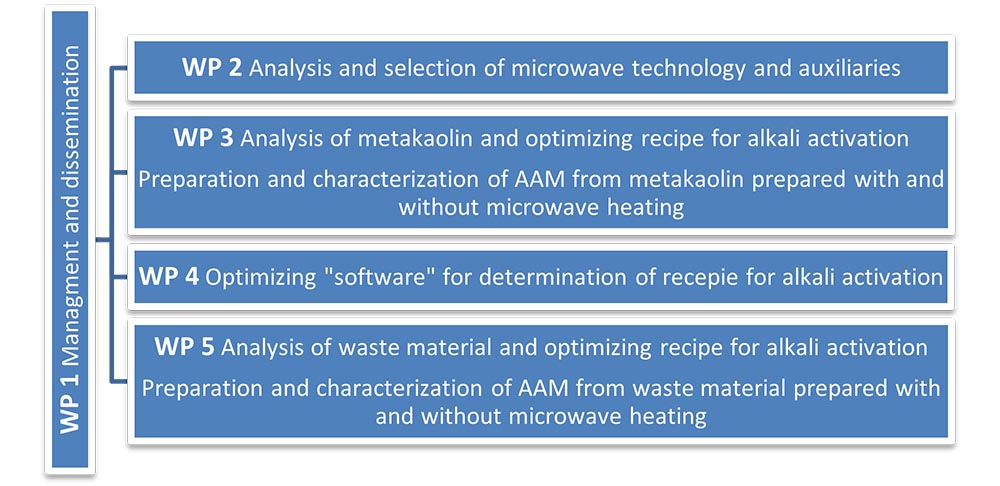

Delo je razdeljeno na 5 delovnih paketov (WP), ki so med seboj povezani, kot je prikazano v diagramu na sliki 3 in podrobno opisano v tabeli 1.

Slika 3. Pertov diagram projekta.

| Tabela 1. Opis delovnih paketov. | |

|---|---|

| WP 1 | Upravljanje projekta in razširjanje rezultatov |

| WP 2 | Analiza in izbor mikrovalovne tehnologije in pomožnih naprav |

| WP 3 | Analiza metakaolina in optimizacija recepta za alkalijsko aktivacijo Priprava in karakterizacija AAM iz metakaolina, pripravljenega z in brez mikrovalovnega segrevanja |

| WP 4 | Optimizacija “programske opreme” za določanje recepta za alkalijsko aktivacijo |

| WP 5 | Analiza odpadnih snovi in optimizacija recepta za alkalijsko aktivacijo Priprava in karakterizacija AAM iz odpadnih snovi, pripravljenih z mikrovalovnim segrevanjem in brez njega |

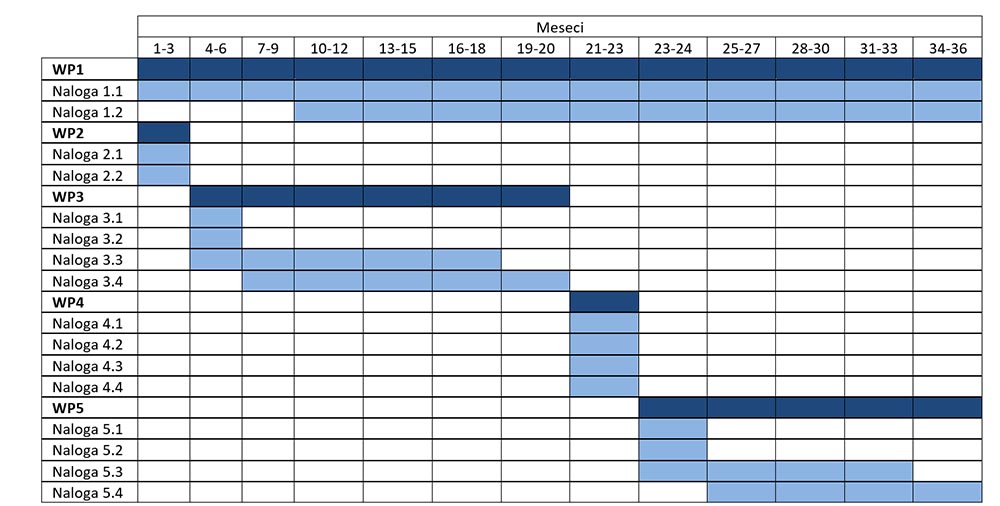

Načrt izvedbe je podan na Slika 4.

Slika 4. Gantt shema projekta.

Faze projekta in opis realizacije (delovni sklopi) EN

Work is divided into 5 work packages (WP) which are interconnected as presented in the diagram on Figure 3 and described in details Table1.

Figure 3. Pert diagram of the project.

| Table 1. Description of work packages. | |

|---|---|

| WP 1 | Management and dissemination of results |

| WP 2 | Analysis and selection of microwave technology and auxiliaries |

| WP 3 | Analysis of metakaolin and optimizing recipe for alkali activation Preparation and characterization of AAM from metakaolin prepared with and without microwave heating |

| WP 4 | Optimizing “software” for determination of recipe for alkali activation |

| WP 5 | Analysis of waste material and optimizing recipe for alkali activation Preparation and characterization of AAM from waste material prepared with and without microwave heating |

The implementation plan is given in Figure 4.